-40%

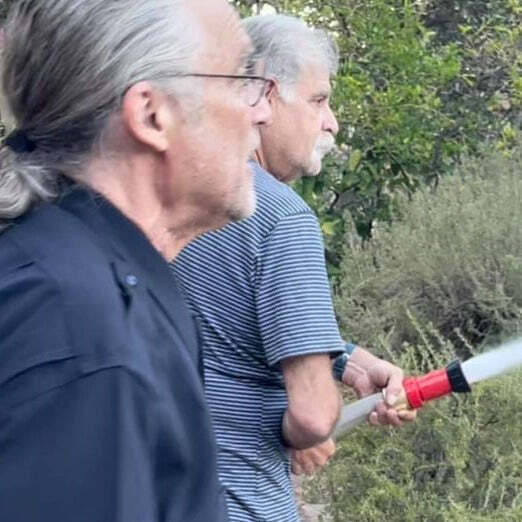

Fire Hose 4 pack 75 ft. x 1-1/2 in. certified and tested.

$ 290.39

- Description

- Size Guide

Description

You are purchasing 4 hoses total length 300 ft.It’s in Serving Each Other We Become Free.

Thank you for visiting our website. We do not take this for granted and are committed to serving you better than anyone else can. We manufacture professional fire fighting gear for your vehicles and home. Our products are certified / tested. Our products are professional fire fighting, water delivery products for First Responders and Steaders.

Stay Safe and God Bless

Do today what others won’t so tomorrow others can.

Outstanding Quality! Outstanding Value!

Hose Size - 1.5 inches (Inside Diameter)

Hose Length - 75 feet (Approximately)

Male Coupling - Brass plated aluminum 1.5 inch NH / NST

Swivel Female Coupling - Brass plated aluminum 1.5 inch NH / NST

The Female Coupling Will Only Connect To A Male 1.5 NH / NST

Compatible Nozzle - 1.5 inch NH / NST only

Hose Type - Polyester Single Jacket (Mildew Resistant)

Color - White

Liner - PU Liner

Approximate Width Laying Flat - 2.5 inches

Service Pressure - 250 PSI

Proof Test Pressure - 500 PSI

Pre-rolled

CCC Approved Standard

Stay Safe and God Bless.

ACE FIRE Hoses are

Single Jacket Reel Fire Attack Hose

Lightweight for home upgrade fire defense plan.

Our reel fire hoses feature a single jacket construction woven from 100% polyester that is lightweight and easy to deploy.

The lining of each reel fire hose is a single-ply extruded tube of synthetic polyurethane /thermoplastic (T.P.U.), designed to be light weight for ease of operator use and increase packing ability for fire preparedness and

firefighting applications. The liner of these reel fire hoses produces a thin, smooth waterway that yields extremely low friction loss for maximum flow rates. The reel hose manufacturing process ensures positive adherence to the jacket to prevent de-lamination.

ACE Fire Hose Manufacturing process.

Ace Fire hose is manufactured in a plant that specializes in providing hose products to municipal, industrial, and forestry fire departments. Here is a typical sequence of operations used to manufacture a double jacket, rubber-lined fire hose.

Preparing the yarn

There are two different fiber yarns that are woven together to form a hose jacket. The yarns that run lengthwise down the hose are called warp yarns and are usually made from spun

polyester

or filament

nylon

. They form the inner and outer surfaces of the jacket and provide abrasion resistance for the hose. The yarns that are wound in a tight spiral around the circumference of the hose are called the filler yarns and are made from filament polyester. They are trapped between the crisscrossing warp yarns and provide strength to resist the internal water pressure. The spun polyester warp yarns are specially prepared by a yarn manufacturer and are shipped to the hose plant. No further preparation is needed.